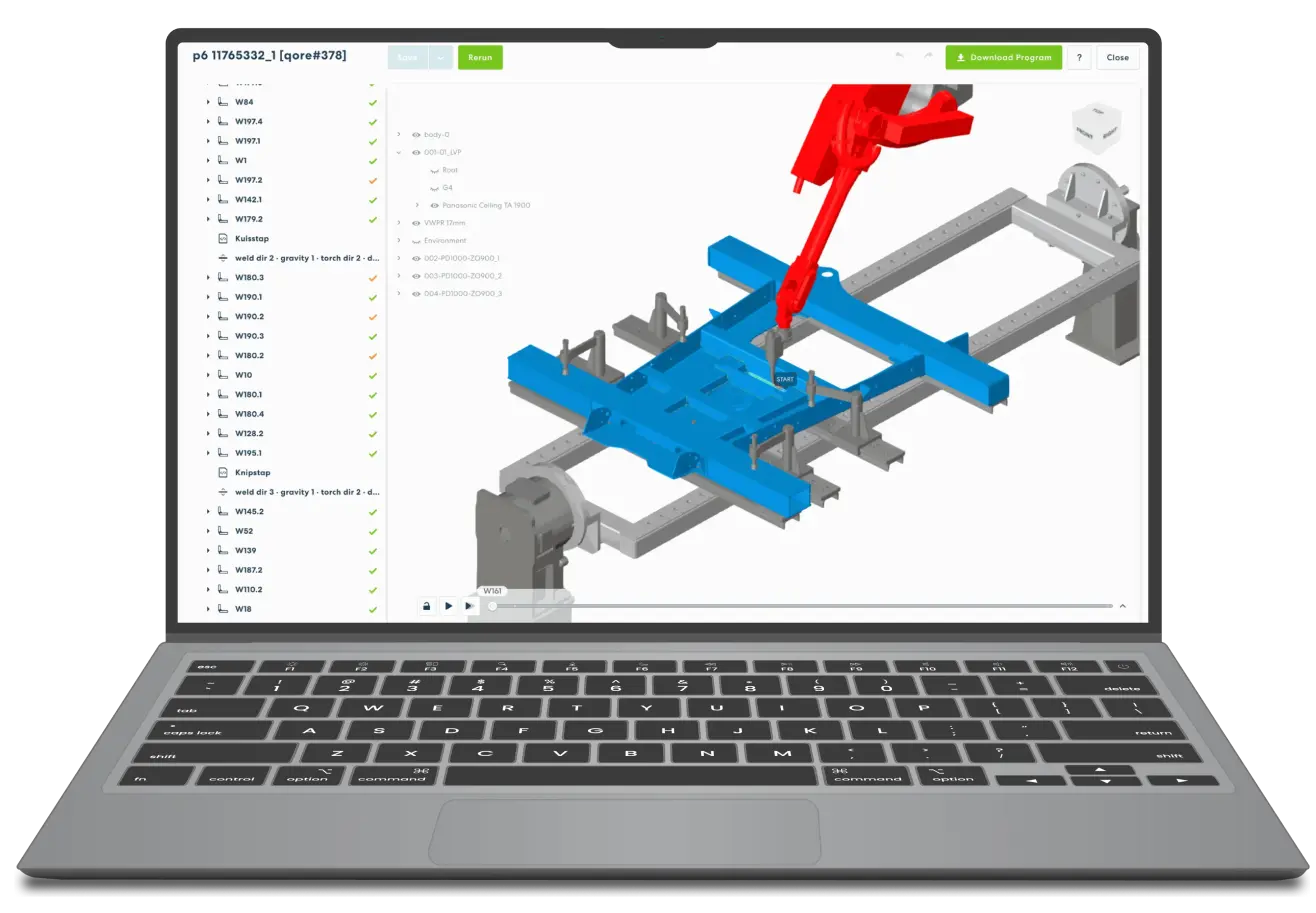

Intuitive interface,

made for welders

The interface is designed for welders, not programmers.

All robot-related complexity is hidden from the user and automatically handled behind the scenes.

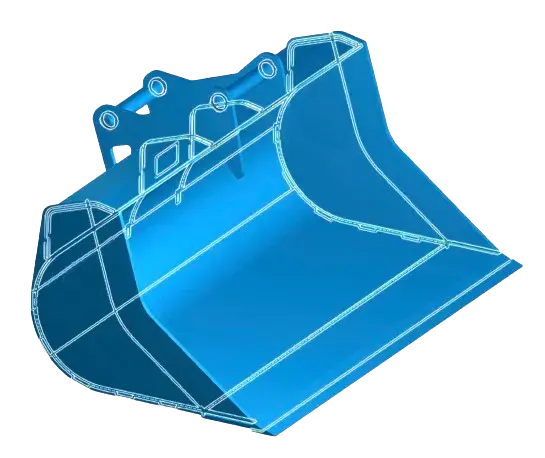

Welds

automatically extracted

ArcNC identifies potential welds on your assemblies automatically.

No need to specify welds inside your CAD drawing.

The weld sequence can be optimised automatically, and adjusted manually.

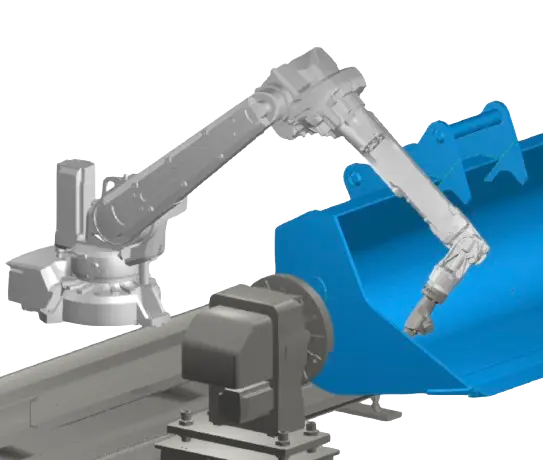

Robot Motions

automatically calculated

Collision-free robot motions are automatically calculated

for welds, sense motions and transitions between them.

Part positioners and additional robot axes (eg. rail) can be controlled synchronously.

Robot singularities, cable stretching or clamping and collisions

are automatically avoided.

Sense Motions

automatically generated

Sense motions are generated automatically to compensate for any deviation between your CAD models and the real world.

Want to get started?

Find out how to use ArcNC to program your robots