Trailer Manufacturing

Ireland and United Kingdom

Mettech, a precision sheet metal fabricator in Ireland, needed a solution to manage frequent part variations in trailer manufacturing. With ArcNC, the team quickly streamlined robot programming.

“Press save and walk away—ArcNC calculates all the robot movements for you” says Kestas, Shopfloor Manager at Mettech.

Transport, spreading & pasture care

Belgium, France, Poland & Luxembourg

After 15 years of programming their welding robots manually, Joskin is switching to ArcNC to drastically reduce the programming time.

“The automatically generated search motions are the biggest advantage of ArcNC. They save us a lot of time, and guarantee perfect welds every time” says Guillaume Balthasart - process engineer at Joskin. “Previously, we manually touched up the program at the start of every new batch.”

Food Industry

Netherlands

"Before ArcNC, programming was too complex, and our welding robot remained unused. Now, we reliably produce parts with flawless seams" says Dennis, Work Preparer at DGS Processing Solutions.

"ArcNC’s intelligent features and intuitive interface transformed our workflow, making robotic welding practical and cost-effective for small batches."

Customized Metal Products

Netherlands

Tol Plaatwerk began using ArcNC a year ago, and the software has significantly enhanced the speed, efficiency, and simplicity of programming their welding robot.

Fred Mol, Welding Coordinator at Tol Plaatwerk, recalls the pivotal moment: "We brought a USB stick with a product file to an event. ArcNC programmed our product on the spot, and we were immediately convinced."

Read more

Timber harvesting and processing equipment

Austria

"Compared to traditional offline-programming solutions, ArcNC is a gamechanger," says Martin Moosbacher (ABB)

Agricultural Equipment

France

"ArcNC brings a fresh wind to programming software," says Charles Verbaere, highlighting the transformative impact on their operations. With its user-friendly interface and powerful capabilities, ArcNC empowers Downs to optimize workflows and maintain their commitment to quality while handling custom, small-batch production efficiently.

Excavator & Machinery Attachments

Northern Ireland

”The ability to reduce a multi-day programming task to a few hours makes ArcNC an invaluable tool,” say Alastair and Simon Hewitt.

Titus Attachments, a leading manufacturer of excavator and machinery attachments in Northern Ireland, recently made a strategic investment in a Valk Welding robot system. ArcNC enabled them to reach full robot capacity in 2 months time.

"In our niche, with a wide variety of low-volume products, we’re always programming in order to reach full machine capacity. ArcNC is a game changer for us."

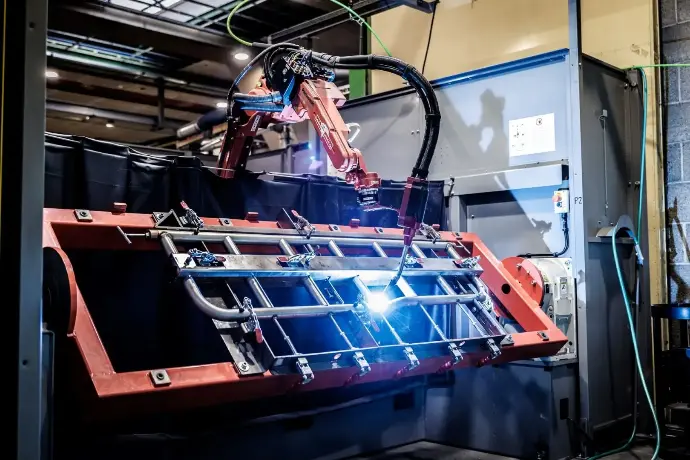

Bridges, stadiums, buildings, off-shore structures, ...

Italy

"Of all the OLP software we have tried, ArcNC is the fastest and the easiest to use, making it an easy choice for us," says Daniele Ottorogo, robotics expert at Cimolai.

"We often found ourselves not using robots for welding because the time saved during production did not outweigh the time needed to program the pieces. Therefore, we began searching for solutions that would allow us a much faster approach to programming and we found ArcNC. "

Industrial Buildings

Belgium

"Creating a program with ArcNC is very easy, the programming time is 6 times shorter than before." says Stijn De Pooter, research and development engineer at Frisomat.

Because of the higher diversity of parts as well as the growing lack of programming capacity, Frisomat is now also taking the step to automate programming with ArcNC. This completely new way of creating welding programs allows them to easily create robot programs for new parts.

Stijn De Pooter further explains: With many more very small series suddenly being considered for the Valk Welding robot installation, the installation is now already sitting at an OEE (Overall Equipment Efficiency) of over 80%. And that's how it should be!

Metal Components

Austria

With ArcNC's new AI software, our ABB welding robot becomes even more efficient. The software enables faster setup and programming of the component, which significantly reduces setup times. In addition, the software can calculate the optimal welding path, increasing production speed without compromising quality. This means shorter production cycles, meaning your product reaches the end customer faster.

The user interface of ArcNC 's AI software has been specifically designed to make it as easy and intuitive to use as possible. Even users without programming knowledge can easily use the software and efficiently control the ABB welding robot. The software also offers comprehensive training materials and support to ensure that your employees can work with the system quickly and easily.

Mobility Solutions

Austria

"We frequently have to weld parts in low quantities. With ArcNC, we can now use the KUKA robot for as little as two-piece production as soon as the welding time exceeds 20 minutes," says Engelbert Froschauer, owner and CEO.

Froschauer GmbH is an innovative metal work shop in Upper Austria, serving their customers in various industries, such as commercial transportation, aerospace and agriculture.

Their business strategy is simple and effective: leverage the newest technologies to stay competitive. For the past 9 months, ArcNC has been helping them to do just that:

Leonhard Breit further explains why they love ArcNC: “We now program parts in under 30 minutes which would previously take multiple hours to program. And because search functions are extremely easy and quick to program, we also save rework time by increasing quality.”

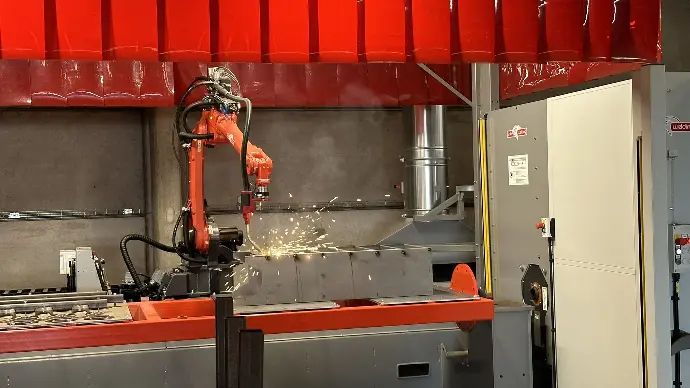

Screening & crushing equipment

Northern Ireland

“I wish we had known about ArcNC a year ago,” says Grzegorz Koszylowski, “the time saving is massive.”

Portafill International Ltd, a leader in crushing and screening equipment in Northern Ireland, deployed two brand new Valk Welding robots last year. All robot programs are now generated automatically using ArcNC.

Portafill is also training colleagues without any prior robot experience. “With ArcNC, they are already creating production programs within a day or two.”

Wire decks, carts & racks

Nashville, Tennessee

Robot: Panasonic

Integrator: Miller Welds